Safety Notes: Safety Technology for Circular Saw Machines

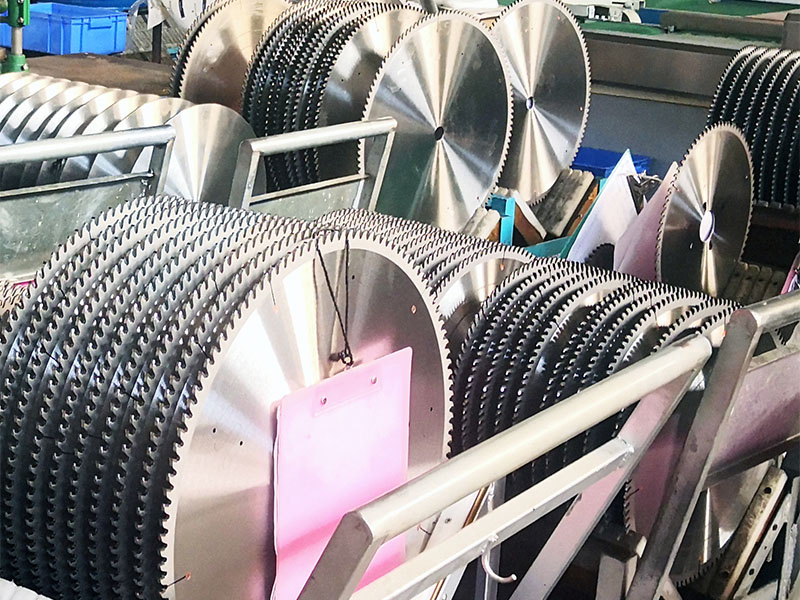

The cutting injury of the saw blade of the circular saw machine and the rebound and projectile injury of the wood are the main dangers.

The manual feeding circular saw must be equipped with a splitting knife; the automatic feeding circular saw must be equipped with a backstop, a pressing device and a side protective baffle, and the feeding roller should be equipped with a protective cover.

Security requirements:

(1) Saw blade and saw shaft

(1) The rotation speed of the saw shaft must not exceed the maximum allowable rotation speed of the circular saw blade.

(2) The saw blade and the flange should be perpendicular to the rotation center line of the saw shaft to prevent the swing of the saw blade when rotating; the saw blade and the flange should be concentric with the saw shaft to prevent unbalanced centrifugal force.

(3) There should be enough contact area between the diameter of the saw blade clamping flange and the saw blade, and the clamping surface must be flat. When turning, there must be no relative sliding between the saw blade and the flange.

(4) Ordinary circular saw blades should be pressed or dialed and sharpened before use, tension treatment and balance inspection and adjustment.

(5) Stop using the circular saw blade if it breaks two teeth continuously or cracks appear, and the circular saw blade is not allowed to be repaired if there are cracks. If the spindle must be locked when changing the saw blade, a spindle locking device shall be provided.

(2) Safety protection device

1. Protection of knives

The exposed part of the circular saw blade can be protected by self-closing or adjustable protection.

2. Splitting knife

The splitting knife is a device set at the discharge end to reduce the extrusion of the wood to the saw blade and prevent the wood from rebounding.

(1) Made of high-quality carbon steel 45 or steel with equivalent performance.

(2) There should be sufficient width to ensure its strength and rigidity. The width is between the thickness of the saw body and the width of the saw material, and the thickness is uniform throughout the entire length.

(3) The leading edge of the distributing knife should be wedge-shaped for easy introduction. The arc radius should not be less than the radius of the circular saw blade.

(4) It should be able to adjust up and down and front and rear directions on the plane of the saw blade. The top of the distribution knife should not be lower than the highest point on the circumference of the saw blade; the distance from the closest point to the saw blade should not exceed 3mm. The distance between the saw blades must not exceed 8mm.

(3) Hand working devices with protective functions

Push bars and blocks made of plastic, wood or plywood should be provided to keep hands away from the blade during machining.

The length of the push rod should not be less than 400mm, the recommended length of the push block is 300-450mm, the width is 80-100mm, and the thickness is 15-20mm. When processing small workpieces and pushing the workpiece against the guide plate, it is recommended to use push blocks.

(4) Exclusion of harmful substances

The removal of sawdust and dust should be considered in the design of the circular saw machine, and the fireproof and explosion-proof should be considered in the dust collection cover or dust collection interface.

The manual feeding circular saw must be equipped with a splitting knife; the automatic feeding circular saw must be equipped with a backstop, a pressing device and a side protective baffle, and the feeding roller should be equipped with a protective cover.

Security requirements:

(1) Saw blade and saw shaft

(1) The rotation speed of the saw shaft must not exceed the maximum allowable rotation speed of the circular saw blade.

(2) The saw blade and the flange should be perpendicular to the rotation center line of the saw shaft to prevent the swing of the saw blade when rotating; the saw blade and the flange should be concentric with the saw shaft to prevent unbalanced centrifugal force.

(3) There should be enough contact area between the diameter of the saw blade clamping flange and the saw blade, and the clamping surface must be flat. When turning, there must be no relative sliding between the saw blade and the flange.

(4) Ordinary circular saw blades should be pressed or dialed and sharpened before use, tension treatment and balance inspection and adjustment.

(5) Stop using the circular saw blade if it breaks two teeth continuously or cracks appear, and the circular saw blade is not allowed to be repaired if there are cracks. If the spindle must be locked when changing the saw blade, a spindle locking device shall be provided.

(2) Safety protection device

1. Protection of knives

The exposed part of the circular saw blade can be protected by self-closing or adjustable protection.

2. Splitting knife

The splitting knife is a device set at the discharge end to reduce the extrusion of the wood to the saw blade and prevent the wood from rebounding.

(1) Made of high-quality carbon steel 45 or steel with equivalent performance.

(2) There should be sufficient width to ensure its strength and rigidity. The width is between the thickness of the saw body and the width of the saw material, and the thickness is uniform throughout the entire length.

(3) The leading edge of the distributing knife should be wedge-shaped for easy introduction. The arc radius should not be less than the radius of the circular saw blade.

(4) It should be able to adjust up and down and front and rear directions on the plane of the saw blade. The top of the distribution knife should not be lower than the highest point on the circumference of the saw blade; the distance from the closest point to the saw blade should not exceed 3mm. The distance between the saw blades must not exceed 8mm.

(3) Hand working devices with protective functions

Push bars and blocks made of plastic, wood or plywood should be provided to keep hands away from the blade during machining.

The length of the push rod should not be less than 400mm, the recommended length of the push block is 300-450mm, the width is 80-100mm, and the thickness is 15-20mm. When processing small workpieces and pushing the workpiece against the guide plate, it is recommended to use push blocks.

(4) Exclusion of harmful substances

The removal of sawdust and dust should be considered in the design of the circular saw machine, and the fireproof and explosion-proof should be considered in the dust collection cover or dust collection interface.