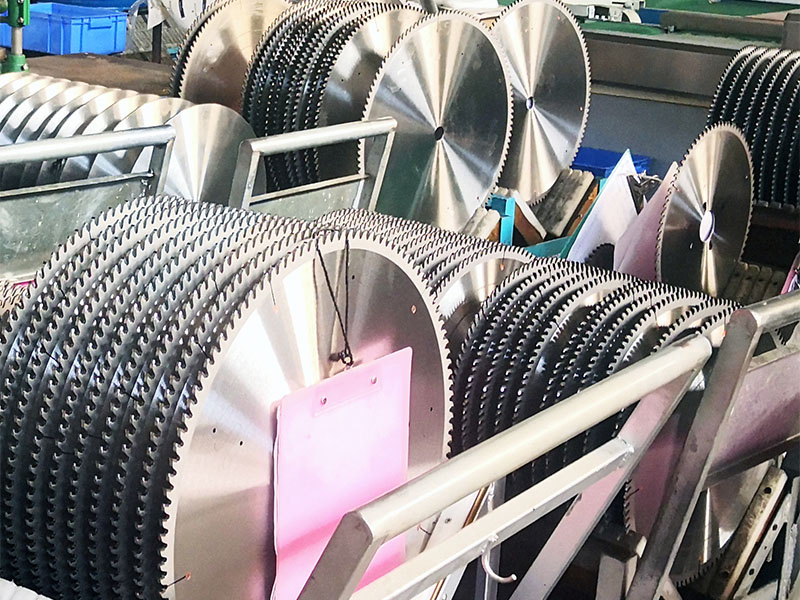

How To Grind Circular Saw Blade In Production | Mask Production Machine

Grinding knowledge of alloy saw blade

1. The grinding fluid is the key to the quality of gear grinding with coolant. A large amount of tungsten and diamond grinding wheel powder are produced during grinding. If the surface of the tool is not washed and the pores of the grinding wheel are not cleaned in time, the surface grinding tool can not grind out the smoothness, and the alloy will be burned without enough cooling.

2. The influence of gear grinding mechanism on gear grinding. The grinding quality of alloy circular saw blade depends on the machine structure and assembly. There are about two types of models in the current market: one is German type. This type uses vertical grinding,

advantage:

All adopt numerical control stepless movement, all feed systems adopt V-type guide rail and ball screw, grinding head or boom adopt feed in slow advance, fast retraction, automatic adjustment center, flexible and reliable support, accurate positioning of tooth pulling, firm and automatic centering of saw blade, arbitrary angle adjustment, reasonable cooling and flushing, realizing man-machine interface and high grinding accuracy The other is horizontal, such as Taiwan and Japan. The mechanical transmission has poor precision of dovetail sliding due to gear and mechanical clearance, low stability of clip, difficult adjustment of support center, poor gear pulling mechanism or reliability, grinding of two sides of plane and left and right rear angles not in one center, resulting in large deviation, difficult angle control and mechanical wear, and it is difficult to ensure the accuracy.

3. Welding factors. When welding, the alloy alignment deviation is large, which affects the grinding accuracy, resulting in a large pressure on one side of the grinding head and a small pressure on the other side. The above factors also occur in the rear angle. The welding angle difference and human unavoidable factors have an unavoidable impact on the grinding wheel and other factors.

4. The influence of grinding wheel quality and grain size width. When grinding alloy sheet with grinding wheel, pay attention to the grain size of grinding wheel. If the grain size is too coarse, the grinding wheel trace will be produced. If the grinding wheel is fine, it is easy to block the grinding volume and burn the cutter. The diameter of grinding wheel and the width and thickness of grinding wheel are determined according to the length, width and width of alloy or the conditions of different tooth profiles and alloy surfaces. It is not possible to grind different tooth shapes arbitrarily with the same grinding wheel specifications at one rear angle or front angle. Therefore, it is necessary to select suitable grinding wheels.

Mask Production Machine

1. The grinding fluid is the key to the quality of gear grinding with coolant. A large amount of tungsten and diamond grinding wheel powder are produced during grinding. If the surface of the tool is not washed and the pores of the grinding wheel are not cleaned in time, the surface grinding tool can not grind out the smoothness, and the alloy will be burned without enough cooling.

2. The influence of gear grinding mechanism on gear grinding. The grinding quality of alloy circular saw blade depends on the machine structure and assembly. There are about two types of models in the current market: one is German type. This type uses vertical grinding,

advantage:

All adopt numerical control stepless movement, all feed systems adopt V-type guide rail and ball screw, grinding head or boom adopt feed in slow advance, fast retraction, automatic adjustment center, flexible and reliable support, accurate positioning of tooth pulling, firm and automatic centering of saw blade, arbitrary angle adjustment, reasonable cooling and flushing, realizing man-machine interface and high grinding accuracy The other is horizontal, such as Taiwan and Japan. The mechanical transmission has poor precision of dovetail sliding due to gear and mechanical clearance, low stability of clip, difficult adjustment of support center, poor gear pulling mechanism or reliability, grinding of two sides of plane and left and right rear angles not in one center, resulting in large deviation, difficult angle control and mechanical wear, and it is difficult to ensure the accuracy.

3. Welding factors. When welding, the alloy alignment deviation is large, which affects the grinding accuracy, resulting in a large pressure on one side of the grinding head and a small pressure on the other side. The above factors also occur in the rear angle. The welding angle difference and human unavoidable factors have an unavoidable impact on the grinding wheel and other factors.

4. The influence of grinding wheel quality and grain size width. When grinding alloy sheet with grinding wheel, pay attention to the grain size of grinding wheel. If the grain size is too coarse, the grinding wheel trace will be produced. If the grinding wheel is fine, it is easy to block the grinding volume and burn the cutter. The diameter of grinding wheel and the width and thickness of grinding wheel are determined according to the length, width and width of alloy or the conditions of different tooth profiles and alloy surfaces. It is not possible to grind different tooth shapes arbitrarily with the same grinding wheel specifications at one rear angle or front angle. Therefore, it is necessary to select suitable grinding wheels.

Mask Production Machine