Safety Notes: Band Sawing Machine Safety Technology

1. Safety technology of band sawing machine

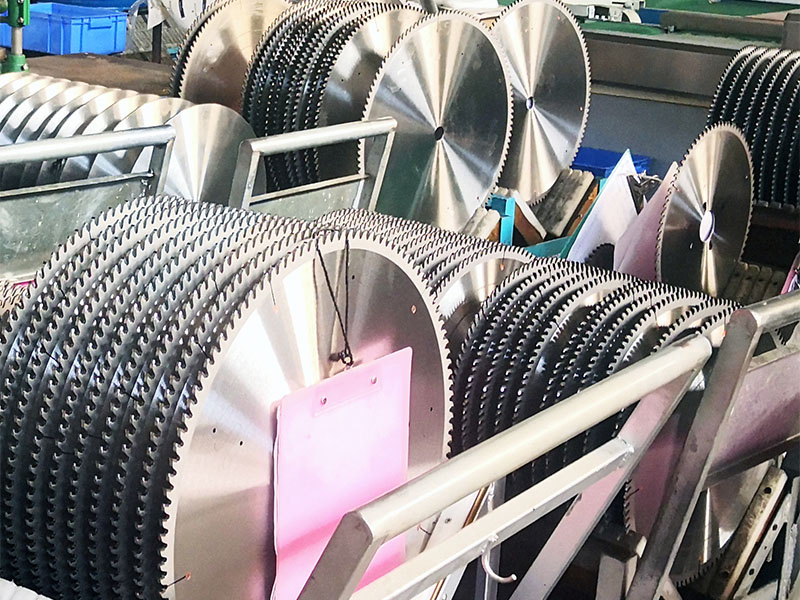

(1) Safety requirements for band saw blades

(1) The saw teeth of the band saw blade should be sharp, and the tooth depth should not exceed 1/4 of the saw width, matching the band saw wheel. Small wheels should not use thick saw blades.

(2) The welding of the saw blade should be firm and flat, the number of joints should not exceed 3, the length between the two joints should be more than 1/5 of the total length, and the thickness of the joints should be basically the same as the thickness of the saw blade.

(3) Strictly control the transverse cracks of the band saw blade, and if the cracks are too long, they should be cut off and re-welded.

(2) Requirements of the control institution

(1) The motorized lifting mechanism of the upper saw wheel should be interlocked with the start-up control mechanism of the Sawing Machine; the lower saw wheel should be equipped with a device that can effectively brake the operation.

(2) An emergency stop control button must be set.

(3) Band Sawing Machine safety protection device

(1) Saw wheel protection. The upper saw wheel is lined with buffer material; at any position of the upper saw wheel, the protective cover should be able to cover more than 3/4 of the saw wheel, and a saw blade receiver should be set at an appropriate place close to the sawtooth edge; when the upper saw wheel is at the highest position, There should be a sufficient distance between the upper end and the lining surface of the protective cover not less than 100mm; the saw wheel and the pulley of the main movement should be subjected to a balance test.

(2) Serrated guards. The serration guard on the cutting edge shall ensure that the non-working serrations are not exposed.

(4) Chip removal, noise reduction, vibration reduction

Noise reduction and vibration reduction measures should be taken, and the maximum sound pressure level of machine tool noise should not exceed 90dB(A) under dry running conditions.

(1) Safety requirements for band saw blades

(1) The saw teeth of the band saw blade should be sharp, and the tooth depth should not exceed 1/4 of the saw width, matching the band saw wheel. Small wheels should not use thick saw blades.

(2) The welding of the saw blade should be firm and flat, the number of joints should not exceed 3, the length between the two joints should be more than 1/5 of the total length, and the thickness of the joints should be basically the same as the thickness of the saw blade.

(3) Strictly control the transverse cracks of the band saw blade, and if the cracks are too long, they should be cut off and re-welded.

(2) Requirements of the control institution

(1) The motorized lifting mechanism of the upper saw wheel should be interlocked with the start-up control mechanism of the Sawing Machine; the lower saw wheel should be equipped with a device that can effectively brake the operation.

(2) An emergency stop control button must be set.

(3) Band Sawing Machine safety protection device

(1) Saw wheel protection. The upper saw wheel is lined with buffer material; at any position of the upper saw wheel, the protective cover should be able to cover more than 3/4 of the saw wheel, and a saw blade receiver should be set at an appropriate place close to the sawtooth edge; when the upper saw wheel is at the highest position, There should be a sufficient distance between the upper end and the lining surface of the protective cover not less than 100mm; the saw wheel and the pulley of the main movement should be subjected to a balance test.

(2) Serrated guards. The serration guard on the cutting edge shall ensure that the non-working serrations are not exposed.

(4) Chip removal, noise reduction, vibration reduction

Noise reduction and vibration reduction measures should be taken, and the maximum sound pressure level of machine tool noise should not exceed 90dB(A) under dry running conditions.