The use and characteristics of the direct supply of the double-head saw cutting machine | Automatic Double End Saw

The use and characteristics of the direct supply of the double-head saw cutting machine:

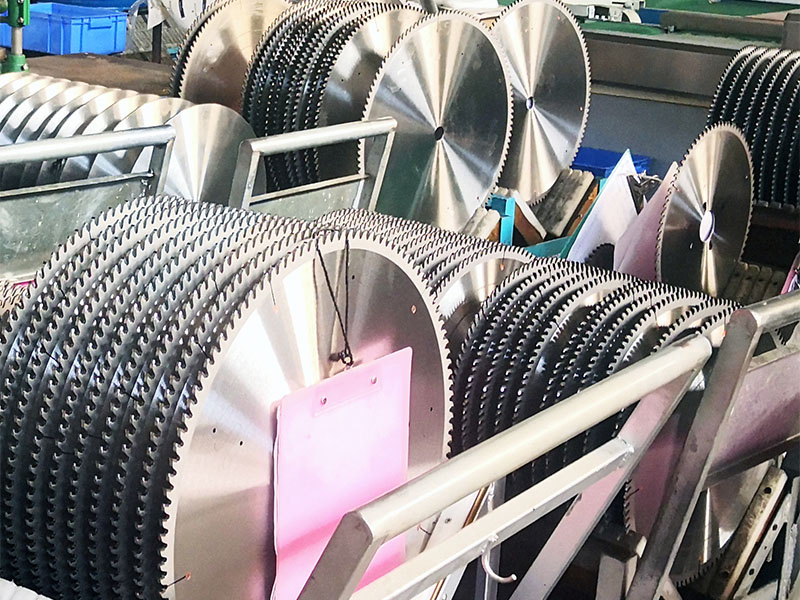

The key to the CNC lathe consists of a protective cover, a material pressing device, a feeding device, a tool spindle power head, a cutting device, a fully automatic oil injection water cooling and moisturizing device, a sound card rack, a support rack, a pneumatic system, and household appliances system software, etc. The key part is composed. It has the following characteristics:

1. Independently innovative suspension swing angle system software (has been awarded a national invention patent) to ensure more accurate angle transformation.

2. The unique swing angle power supply circuit and mechanical design make the saw blade not easy to damage the backing box and damage the saw blade.

3. The novel style organization ideally maintains the swing angle and clamping operation, making the actual operation easy and convenient.

4. The handle of the movable case is moved horizontally to adjust the length of sawing, and there is a digital display screen to display the information and its marked value.

5. Improve the protection design of the rear and front sides of the chassis to ideally prevent the sawdust from polluting the system software on the rear side.

6. The front door of the chassis body is changed into a door handle to cover the door. It is unique and convenient for removing sawdust and removing saw blades.

The processing technology of products from large manufacturers and small workshops is not just one point or two. Even if a small workshop looks like the surface, it cannot be compared with brand doors and windows in terms of all the performance of doors and windows.

In the design of doors and windows, technical interior designers design not only the appearance, but the doors and windows that are more suitable for the actual application and can enhance the value of the goods. How to make the door and window sealing strip perform better, how to make the door and window use longer, the small workshop can imitate the appearance design but can not imitate the real design plan.

In terms of the accuracy of laser cutting of doors and windows, the precision of machinery and equipment in small workshops is poor. The cost of selling 400 flat doors and windows will only be 200, while the cost of selling 800 doors and windows will be six or seven hundred, and the cost of selling 2000 doors and windows will be more than 156.

Tightness = comfort

Comfort is the level of a person's leisurely experience of his surroundings. "Comfort" is only a subjective perception, and there is no uniform standard. The key to the feeling of comfort lies in the reflection of the heat and cold sensation that manipulates the balance of heat generated by the human body. The human body is more sensitive to the infiltration of cold air into the building. "Cold air infiltration" is generally understood as the partial refrigeration of the human body caused by the fluidity of non-hot gas.

The cold air injected from an unsealed location will cause uneven room temperature and surface temperature: the incoming cold outdoor air produces a downward shifting cyclone, which reduces the surface temperature of building components and creates a "cold air sea" on the wooden floor. When a person stands up with a temperature difference of 2 degrees between the foot and the top of the head, the human body will experience discomfort. People will also feel uncomfortable when the surface temperature of the building components is more than 4 degrees away from the room temperature.

When you choose a window shop, even if the door and window process is more than half done, you can't take it lightly. You have to urge the door and window merchants to deal with it in time, pay the money to sign the contract and place the window order to the factory as soon as possible.

There are also some windows that can only be measured after the mason knocks on the wall or builds the wall. In order not to delay the progress, you can ask the mason to make the wall of the window first. Once the wall is in place, immediately let the window merchant measure and download Single drop.

So before knocking on the wall, place an order for the window, and you can’t drag it until the wall is built, and the window has not been ordered yet.

Automatic Double End Saw

The key to the CNC lathe consists of a protective cover, a material pressing device, a feeding device, a tool spindle power head, a cutting device, a fully automatic oil injection water cooling and moisturizing device, a sound card rack, a support rack, a pneumatic system, and household appliances system software, etc. The key part is composed. It has the following characteristics:

1. Independently innovative suspension swing angle system software (has been awarded a national invention patent) to ensure more accurate angle transformation.

2. The unique swing angle power supply circuit and mechanical design make the saw blade not easy to damage the backing box and damage the saw blade.

3. The novel style organization ideally maintains the swing angle and clamping operation, making the actual operation easy and convenient.

4. The handle of the movable case is moved horizontally to adjust the length of sawing, and there is a digital display screen to display the information and its marked value.

5. Improve the protection design of the rear and front sides of the chassis to ideally prevent the sawdust from polluting the system software on the rear side.

6. The front door of the chassis body is changed into a door handle to cover the door. It is unique and convenient for removing sawdust and removing saw blades.

The processing technology of products from large manufacturers and small workshops is not just one point or two. Even if a small workshop looks like the surface, it cannot be compared with brand doors and windows in terms of all the performance of doors and windows.

In the design of doors and windows, technical interior designers design not only the appearance, but the doors and windows that are more suitable for the actual application and can enhance the value of the goods. How to make the door and window sealing strip perform better, how to make the door and window use longer, the small workshop can imitate the appearance design but can not imitate the real design plan.

In terms of the accuracy of laser cutting of doors and windows, the precision of machinery and equipment in small workshops is poor. The cost of selling 400 flat doors and windows will only be 200, while the cost of selling 800 doors and windows will be six or seven hundred, and the cost of selling 2000 doors and windows will be more than 156.

Tightness = comfort

Comfort is the level of a person's leisurely experience of his surroundings. "Comfort" is only a subjective perception, and there is no uniform standard. The key to the feeling of comfort lies in the reflection of the heat and cold sensation that manipulates the balance of heat generated by the human body. The human body is more sensitive to the infiltration of cold air into the building. "Cold air infiltration" is generally understood as the partial refrigeration of the human body caused by the fluidity of non-hot gas.

The cold air injected from an unsealed location will cause uneven room temperature and surface temperature: the incoming cold outdoor air produces a downward shifting cyclone, which reduces the surface temperature of building components and creates a "cold air sea" on the wooden floor. When a person stands up with a temperature difference of 2 degrees between the foot and the top of the head, the human body will experience discomfort. People will also feel uncomfortable when the surface temperature of the building components is more than 4 degrees away from the room temperature.

When you choose a window shop, even if the door and window process is more than half done, you can't take it lightly. You have to urge the door and window merchants to deal with it in time, pay the money to sign the contract and place the window order to the factory as soon as possible.

There are also some windows that can only be measured after the mason knocks on the wall or builds the wall. In order not to delay the progress, you can ask the mason to make the wall of the window first. Once the wall is in place, immediately let the window merchant measure and download Single drop.

So before knocking on the wall, place an order for the window, and you can’t drag it until the wall is built, and the window has not been ordered yet.

Automatic Double End Saw