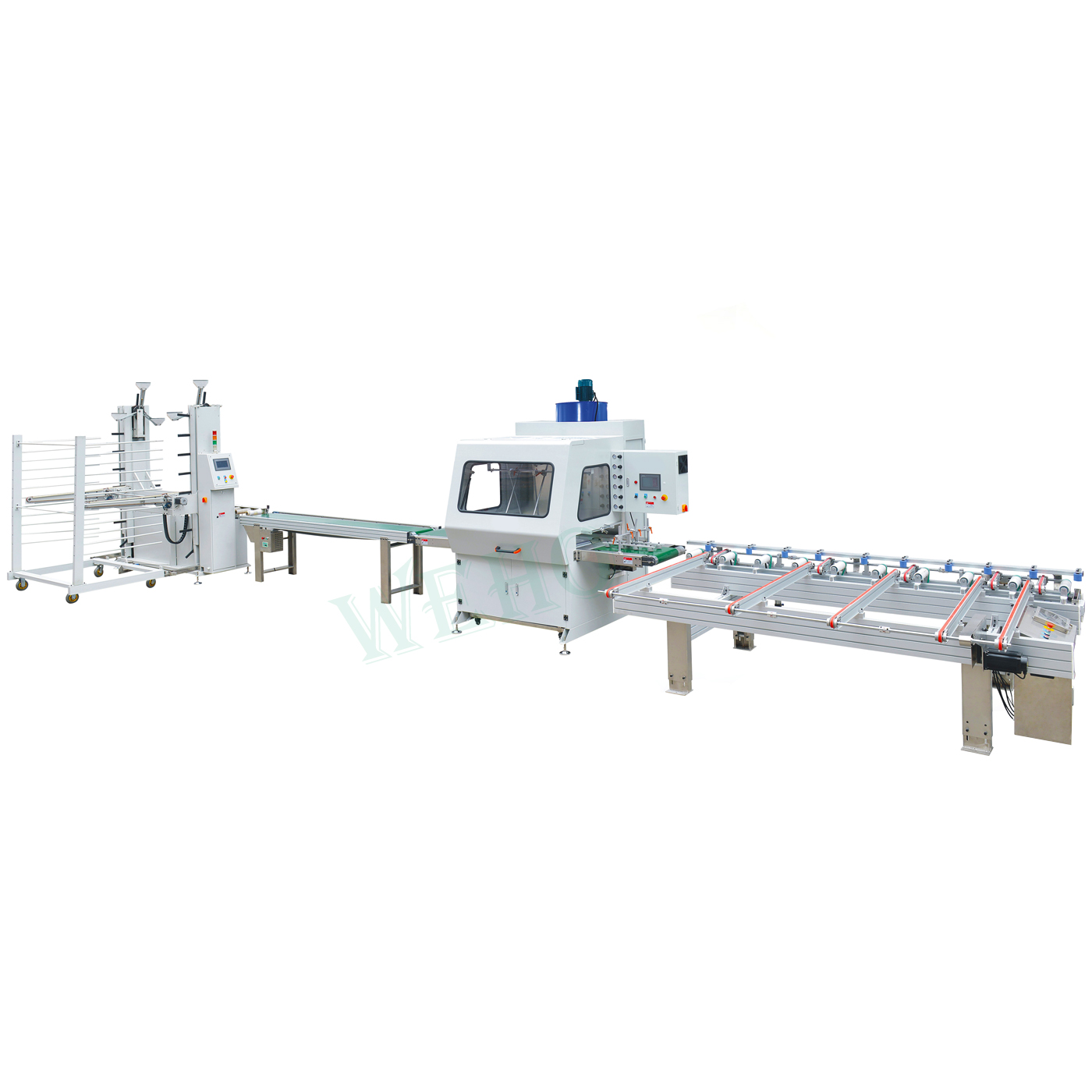

| Model | HL-P300A |

| Processing length | 600-1500mm |

| Processing width | 80-200mm |

| Processing thickness | 20-80mm |

| Conveying speed | 10-35m/min |

| Transmission inverter power | 0.4KW (variable frequency) |

| Conveying motor power | 0.4KW |

| Exhaust fan power | 3KW |

| Total power | 5.75KW |

| Voltage | 380V |

| Number of spray guns | 6 (including spray guns) |

| Mechanical size | 2300*2000*2300 (as per the actual) |