- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

Horizontal furniture wood floor sanding multi roller bursh sponge sander machine for hardwood flooring

Model:DP1000-6;DP1300-6

Max machining width:1000mm;1300mm

Max machining thickness:110mm

Conveyor speed:5-30m/min

Diameter of screw roller:300mm

Power (kW):10.63

Max machining width:1000mm;1300mm

Max machining thickness:110mm

Conveyor speed:5-30m/min

Diameter of screw roller:300mm

Power (kW):10.63

Details

Spare Parts

Inquiry

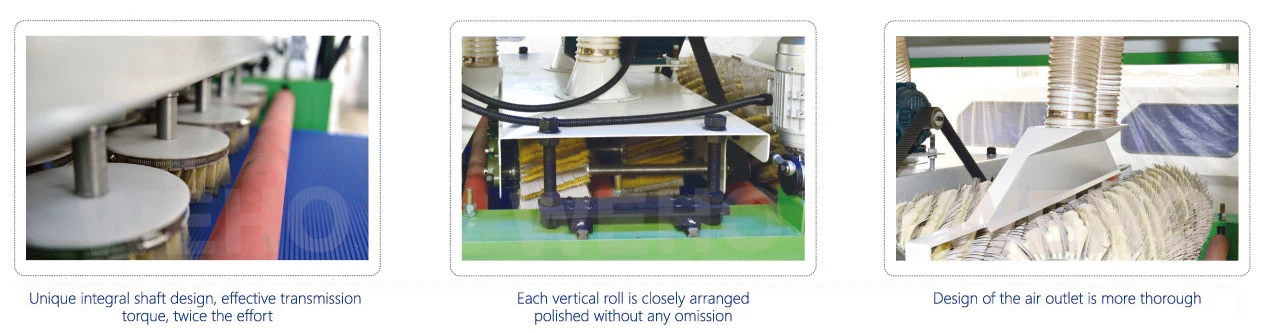

Roller brush processing mode can adapt to all kinds of plane,inclined plane,surface,concave and convex surface,special-shaped surface grinding sanding avoid sand belt when machining can't sand surface and flat straightness too demanding of the machining surface defects.

| Model | DP1000-6 | DP1300-6 |

| Max machining width | 1000mm | 1300mm |

| Max machining thickness | 110mm | 110mm |

| Spiral roller speed control mode | Frequency control | Frequency control |

| Conveyor speed | 5-30m/min | 5-30m/min |

| Lifting motor power | 0.37kw | 0.37kw |

| Brush disc motor power | 2.2kw/1.5kw | 2.2kw/1.5kw |

| Roller motor power | 2.2kw/1.5kw | 2.2kw/1.5kw |

| Motor power of the spiral roller | 2.2kw*2 | 2.2kw*2 |

| Oscillating motor power | 0.18kw*2 | 0.18kw*2 |

| Delivery motor power | 1.1kw | 1.1kw |

| Total power | 10.63kw | 10.63kw |

| Brush tray diameter | 180mm | 180mm |

| Brush plate no. | 9 | 9 |

| Vertical roller no. | 5 | 5 |

| Rolls no. | 2 | 2 |

| Diameter of screw roller | 300mm | 300mm |

| Overall dimensions | 3500*1650*1700mm | 3500*2000*1700mm |

| Weight | 1500KG | 1700KG |

It adpots unique sand roller setting method,which is more suitable for wood processing principle,and has good processing effect on each concave and convex surface.Adopt to all kinds of rough craft requirements.

New and practical high efficiency of various plane,special-shaoed plate surface pricessing equipment.

Each unit is controlled by frequency converter,and each unit can be assembled freely according to the process.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design

and manufacture most of wood processing machines.Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

and manufacture most of wood processing machines.Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

[]

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.