- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

Four cutter planer industrial wood molding machine

Model:M623

Working width:25-230mm

Working thickness:8-100mm

Working table length:1970mm

Feeding speed:6-36

Power:39.55KW

Working width:25-230mm

Working thickness:8-100mm

Working table length:1970mm

Feeding speed:6-36

Power:39.55KW

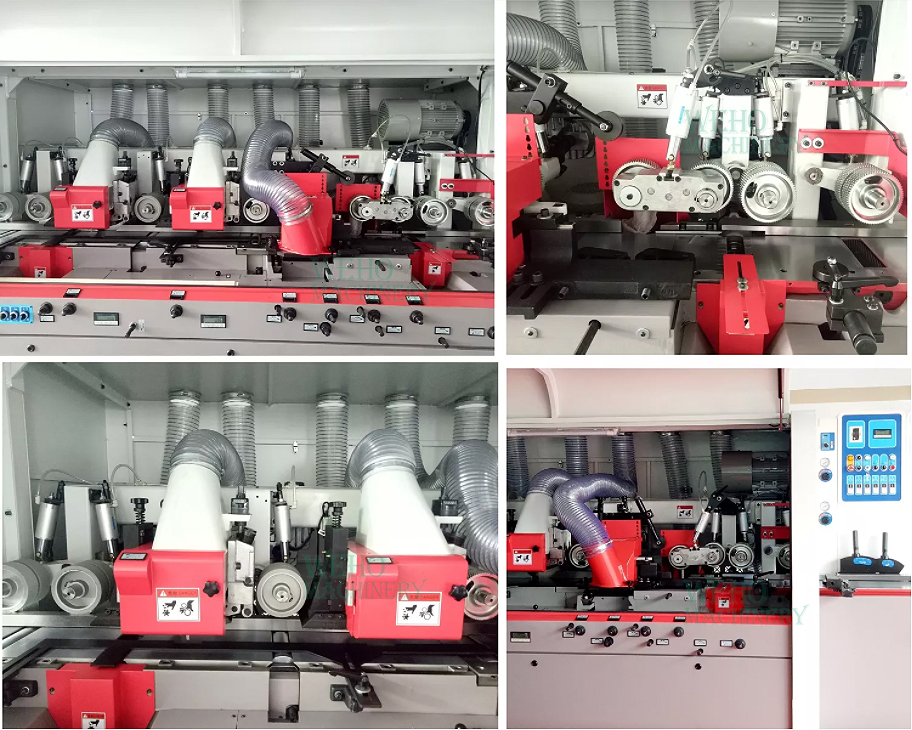

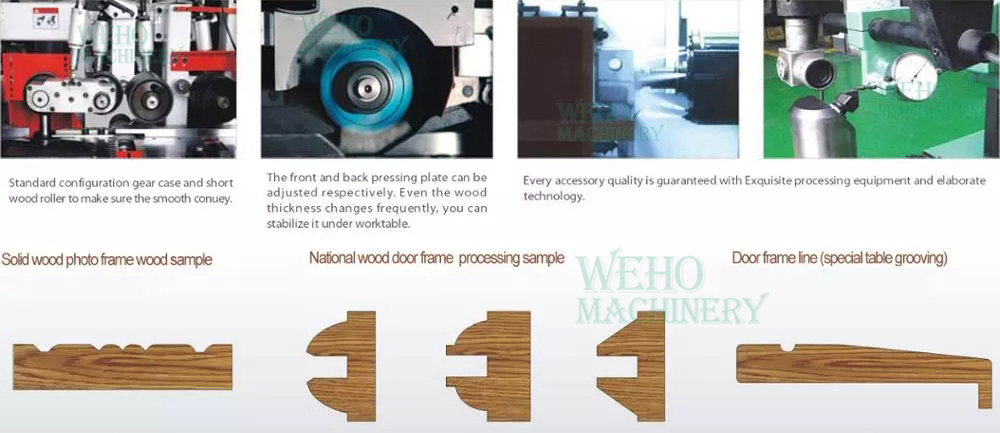

Details

Spare Parts

Inquiry

12-230 mm width moulding capacity(different model with different working size). Full coverage sound cover/safety enclosure is optional. Long infeed table and fence for straightening. Precision sealed long life bearing. Industrial full power motor for maximum cutting capacity. High quality famous brand electric parts.

| Produce name | Four cutter planer industrial wood molding machine |

| Model | M623 |

| Working width | 25-230mm |

| Working thickness | 8-100mm |

| Working table length | 1970mm |

| Feeding speed | 6-36 |

| Mian spindle diameter (mm) | Φ 40 |

| Main spindle revolution (r/min) | 6500 |

| Air pressure (Mpa) | 0.6 |

| 1st Lower Shaft | 5.5KW/7.5HP |

| Right vertical spindle | 5.5kw/7.5HP |

| Left vertical spindle | 5.5kw/7.5HP |

| 1st Upper Shaft | 7.5kw/10HP |

| 2nd Upper Shaft | 5.5KW/7.5HP |

| 2nd Lower Shaft | 5.5kw/7.5HP |

| Feeding beam lifting | 0.55kw/0.75HP |

| Feeding motor | 4kw/5.5HP |

| Total power | 39.55kw/54.3HP |

| 1st Lower Shaft | Φ 125 |

| Right Vertical spindle | Φ 125-Φ 180 |

| Left vertical spindle | Φ 125-Φ 180 |

| 1st Upper Shaft | Φ 125-Φ 180 |

| 2nd Upper Shaft | Φ 125-Φ 180 |

| 2nd Lower Shaft | Φ 125-Φ 200 |

| Feeding wheel diameter (mm) | Φ140 |

| Dust outlet diameter (mm) | Φ140 |

Whole body adapt casting iron, stable performance and high rigidity.

Fully-enclosed safety cover and door opening protection, low noise, safety and environmental protection.

Main shaft is precision-machined, balanced, and assembled accurately, keep high precision and stable operation even many years using.

Feeding system front and middle and rear use three cylinder press, stable pressure, easy adjustment.

Four sided moulder combines high efficiency with heavy duty operation and comes with a sound reputation for maximum dependability.

Working table surface adopts special materials and special heat treatment, hard chrome plating is thicker than others, wear-resistance, ensure working table long time using.

Our machine control quality from steel machinery, thicker steel ensure machine rotating without vibration. Completed processing ensure machine base not deformated in many years.

Four Cutter Planer

[]

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.